When trolling for used PC parts deals, you often don't get to pick and choose the exact parts combinations for builds and have to figure out how to work with what luck brings your way. Lucky for me, I think builds are much more interesting when the parts don't quite fit together without some hacking and creativity!

Even with the recent trends towards more clean front PC cases, I like direct front to back airflow setups, and being as I have not had extra budget in any build to use a premium case, the entry level Corsair SPEC-01 accurately fits my cheap style. When this one came up on Craigslist at roughly half of current retail price, I jumped on the opportunity.

The Kraken X61 is a bit of a gamble and I still don't know if it will pay off. The various stickers on the box indicate that this unit was sold at some point by NCIX and was returned with the reason being "did not fit". If the clues are accurate, I'm hoping it does not exhibit any other manufacturing defects and can run for the designed 6 years. But if not, I lose because Kraken requires the original purchase receipt for warranty service and I do not have that! Another problem may be the negative reviews I read about the CAM software required to set up the device. As this will likely be a used parts budget build, I'm hoping I don't have to contend with a piece of software that eats up 3% or more of my system resources all the time. But, with some luck everything will work out ok.

The first step is to remove the front face of the SPEC-01 by pulling on the large bottom tab. This may put up quite a bit of resistance the first few times.

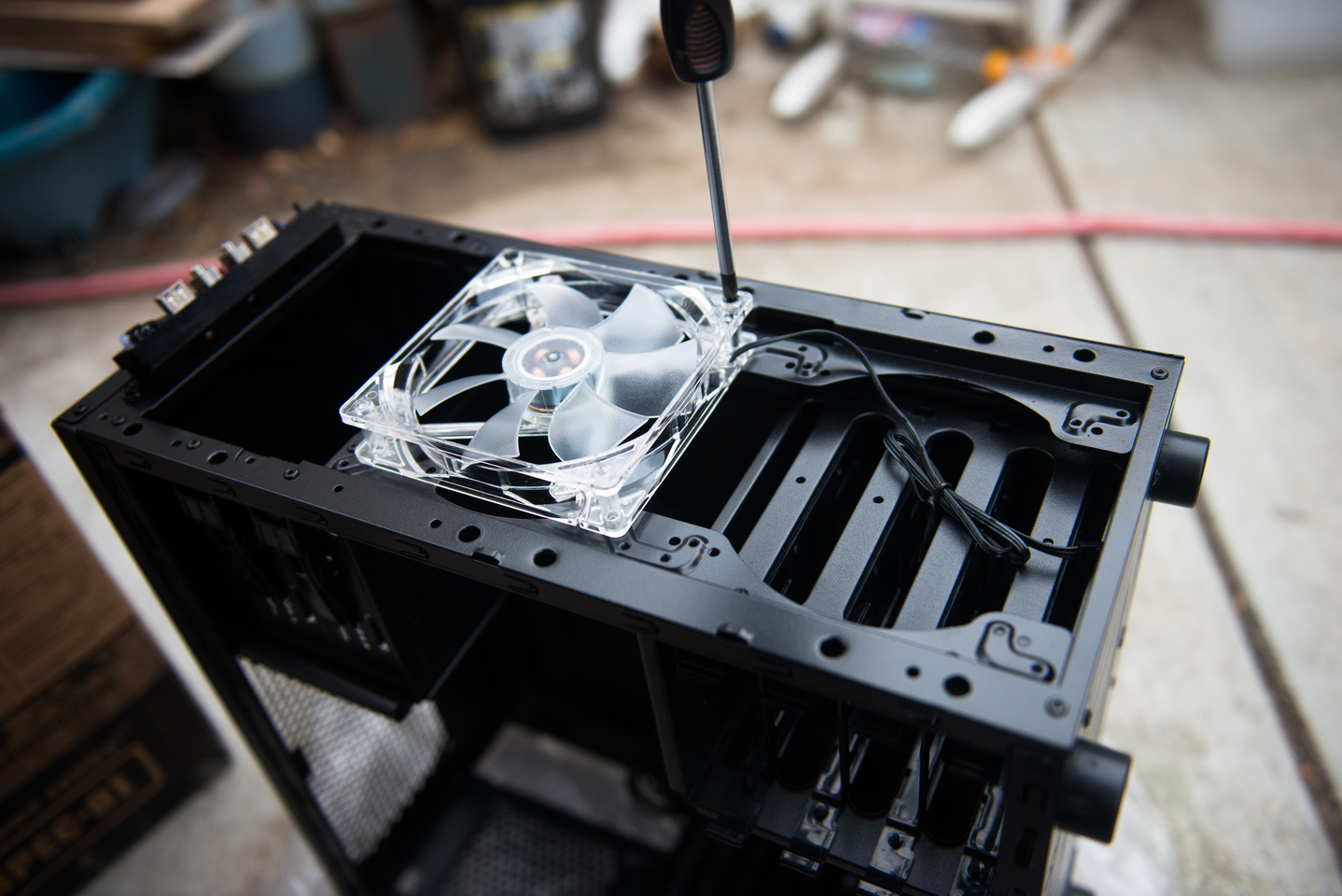

This will expose the single red LED illuminated 120mm fan that comes with the case. Four screws remove this fan.

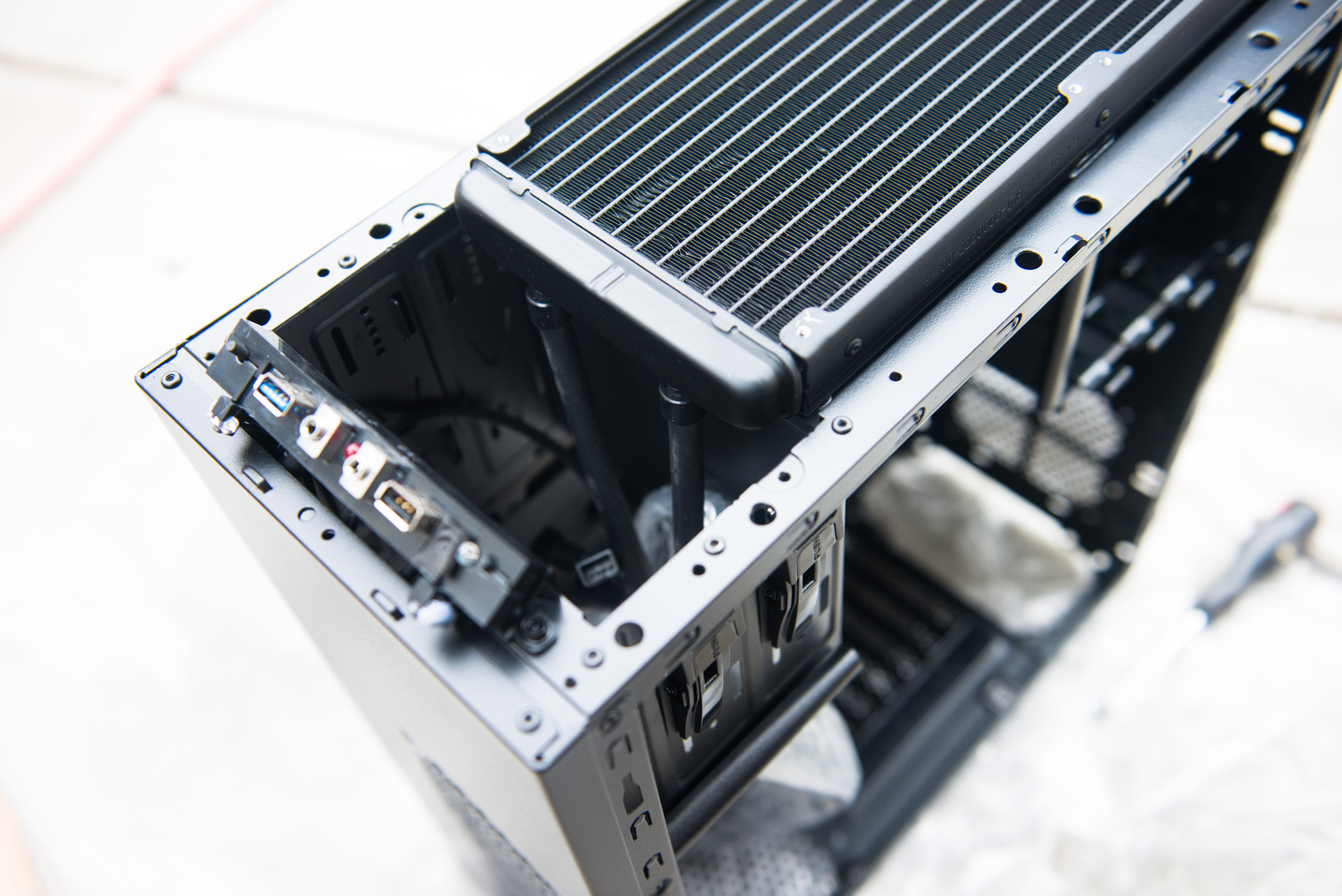

I decide that the most straight-forward place to mount the 280 radiator is right behind the front cover in this position. On the bottom side, we see the bottom lip of the case obstructing the radiator's reservoir.

On the top side, there are no physical obstructions to mounting the radiator, but the rubber tubes will need to pass directly through the bottom 5.25" drive bay which will reduce the expandability of the case, but should be a pretty clean and seamless solution.

So, the first order of business is to cut the bottom of the case for the radiator reservoir to clear. I used some blue painter's tape to clearly mark the cutout area.

And a fiber reinforced dremel cutoff wheel goes through the thin sheetmetal with ease. Is that a "feature" on cheap cases? Maybe.

After some cleanup with a file, this is what we end up with.

The case is definitely weakened a little bit, but once the radiator is screwed into position, it should add back a bit of lost rigidity.

And, here we have our mount position for the radiator. Nice and clean with minimal case cutting!

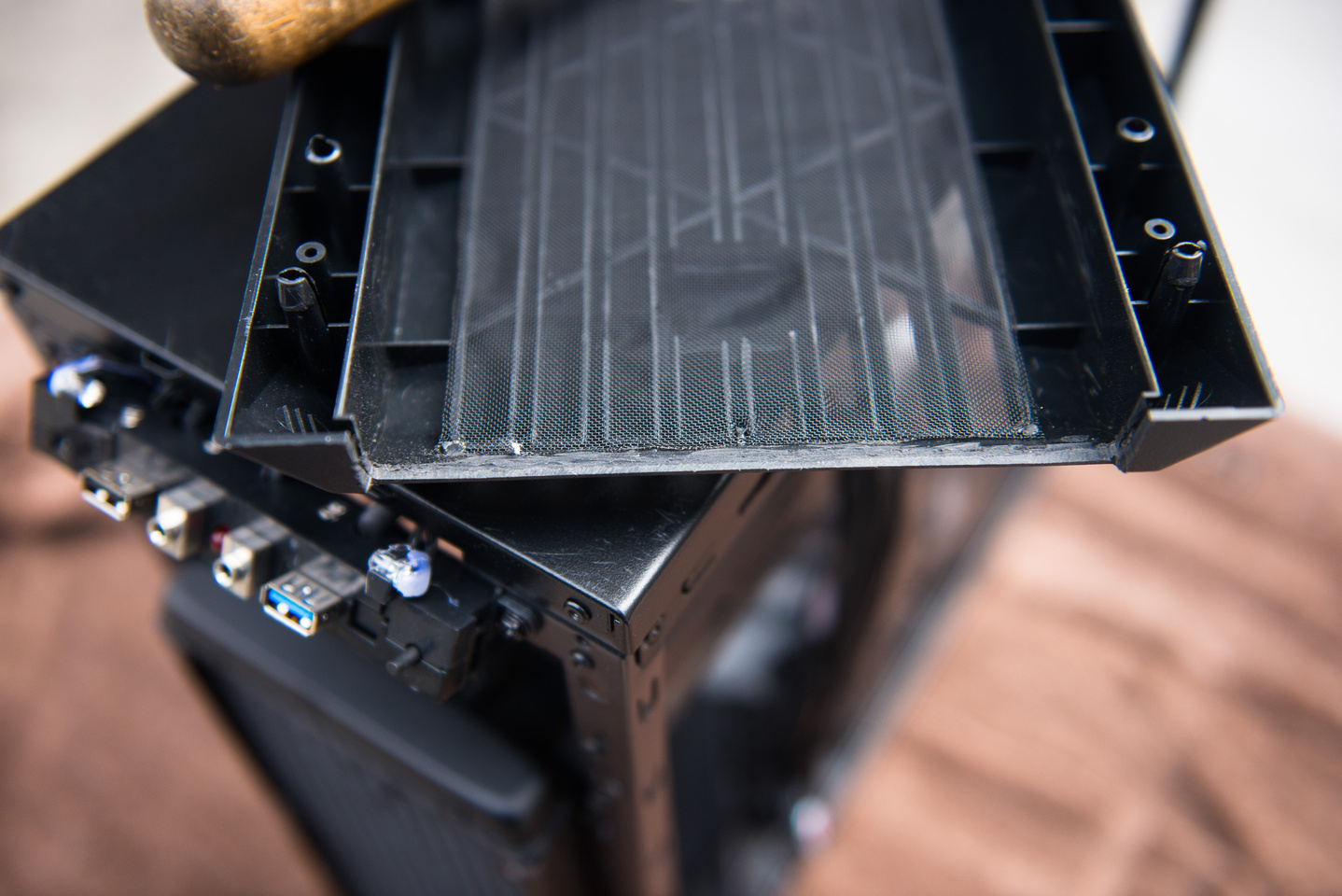

Turning my attention to the plastic front cover, there are definitely some new obstructions that will need to be dealt with. Because the top of the radiator is intruding into the 5.25" drive bay area, I will need to make a few cuts to the plastic plate. The front cover was only intended to accept two 140mm fans and the reservoirs protrude further that this at the top and bottom.

This flat plastic section will need to be removed.

The dremel cutoff wheel works fine to cut the plastic, even if it is a bit "melty" and I use a wire cutter to chop the small ends because the cutoff wheel is difficult to maneuver into that position.

Here you can see the radiator clearance after the cut is made.

The next obstruction is the bottom reservoir on the radiator. A notch cut will need to be made on the front cover to make it sit flush.

Again, I used blue tape to mark the cut area, but this time, I stayed a bit outside of the final line with the dremel and used a file to slowly close the distance to the tape line. The dremel is way too "melty" to make a clean line on the plastic.

The first cut attempt was a little bit short and the front cover still had a gap, so I had to re-mark the area and make a second cut

The second cut was also a little bit shallow, but I was close enough that I could close the remaining gap slowly with a file. This way, I cut the least amount of material possible so the front cover can retain as much structure as possible after the hack. I thought about reinforcing the area behind with some aluminum or brass sheets epoxied in, but the cover felt strong enough without additional reinforcement.

At this point, I removed the bottom drive cage from the case and tried screwing in the 140mm fans from inside of the case, but discovered that the case was only designed to accept fans on the front side directly under the front cover. Because the radiator now occupies that space, it is impossible to mount the top 140mm fan behind the radiator.

The bottom of the 5.25" drive bay prevents the fan from fitting.

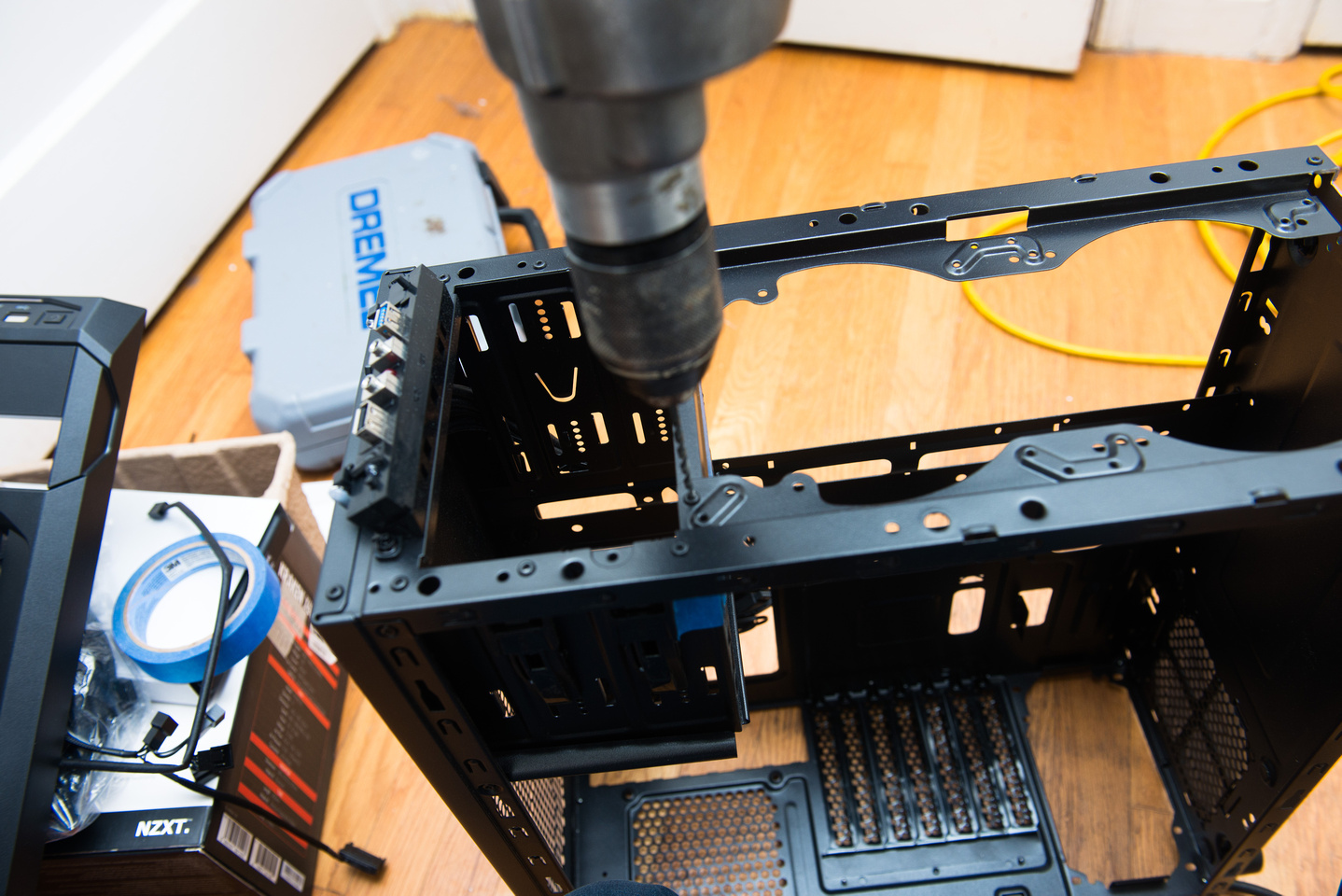

One solution would be to simply mount a 120mm fan in the top position, but after thinking about it for a bit, later that evening, I decided the bottom 5.25" bay is occupied by the rubber hoses coming off of the radiator and can't be used anyways, I might as well make the cut I need to mount the proper 140mm fan from the back side.

Again, I mark my cut line with some blue tape.

This cut will require drilling out two rivets to release the metal panel.

And, I am able to make the cut with a cutoff wheel again. There is a bit of an angle at the end because the cutoff wheel was difficult to maneuver into that spot from this angle. I came in from the other side of the panel on a second pass to clean that up.

And, here is the clearance cut for the top 140mm fan completed.

This case was tapped and drilled for fan installation, those threads make it difficult to seat the radiator all the way flush with the sheetmetal tabs. Because we are sandwiching the metal tabs between the fans and radiator, I decided to drill out the screw threads on all of the fan mount holes so when I tighten down my fan screws into the radiator, the radiator will be able to settle all the way down to the metal tabs.

And that is all for the case mod! With the clearance cut, both 140mm fans now fit without issue.

The Kraken X61 has long enough rubber tubes to reach the CPU. I know not all AIO's will reach, but this one will work. There also looks to be plenty of room for a reservoir and pump for a custom loop if that is an upgrade path in the future. Unfortunately, the bottom drive bay will not go back in with the fans mounted in this position. This shorter corsair drive cage could work on the bottom because I believe it is short enough to stay under the motherboard.

CORSAIR DRIVE CAGE

But, at this point, the mod is complete, and I feel the 280 radiator slots in very discretely under the front cover.

Here are the cuts that were made to the front cover in order to clear the radiator.

And the cover in place!

Humans win!

This comment has been removed by a blog administrator.

ReplyDeleteThis comment has been removed by a blog administrator.

ReplyDeletewww.webroot.com/safe:Webroot is a private American company that provides comprehensive internet security solutions for consumers as well as businesses with various products. These services are available for home based computers, small offices as well as large business enterprises by preventing potential dangers in real time whenever they connect in the digital space for both personal and professional purposes.

ReplyDeleteWebroot Antivirus

ReplyDeleteIdeal for PCs and Macs, this scans at super-fast speed, protects from identity thefts and does not have time-consuming updates that are common with most antivirus products. You can buy this only for $XX.XX for one device for one year to start with. Check out www webroot com safe

Webroot.com/safe

enter kaspersky activation code – As people all around the world carry out their everyday work on their official and personal computers, they require total security against all kinds of threats that these virus files can cause. Using kaspersky internet security make you feel safe and provides you the safety shields to stop malicious files from entering in the Desktop, laptop, smart phones via malware, , root-kit, spyware and Trojan horses. These viruses are originated randomly from old PC-stuck files or suspicious Trojan horse, spyware and malware online websites. So protect your device with Kaspersky total security.

ReplyDeleteenter kaspersky activation code

Kaspersky Antivirus

ReplyDeleteProtecting you… starts with protecting your laptop. That’s why our essential laptop protection defends against viruses, ransomware, phishing, spyware, dangerous websites and more.

i have kaspersky activation code

enter kaspersky activation code– As people all around the world carry out their everyday work on their official and personal computers, they require total security against all kinds of threats that these virus files can cause.

ReplyDeletei have kaspersky activation code– As people all around the world carry out their everyday work on their official and personal computers, they require total security against all kinds of threats that these virus files can cause.

ReplyDeletekaspersky download already purchased– As people all around the world carry out their everyday work on their official and personal computers, they require total security against all kinds of threats that these virus files can cause.

ReplyDeletekaspersky download and install– As people all around the world carry out their everyday work on their official and personal computers, they require total security against all kinds of threats that these virus files can cause.

ReplyDeletekaspersky download with activation code-This antivirus software scans every website and blocks the access to the malicious and damaging websites of the browser.

ReplyDeleteinstall-webroot-with-key-codeR- Experience next-generation Security level with Webroot on your all devices. Install and activate webroot from www webroot com safe and don’t forget to run webroot safe scan to feel secure anywhere. webroot.com/safe is a computer security software program for Microsoft Windows users that combine software as a service cloud protection with traditional Antivirus and anti-spyware desktop technologies. Built into the suite is a two-way firewall, a registry cleaner, Email anti-spam, secure browsing, anti-phishing and a password management service. The suite was initially released on July 26, 2010, as the 2011 version of the product.

ReplyDeleteHi there,I enjoy reading through your article post, I wanted to write a little comment to support you and wish you a good continuationAll the best for all your blogging efforts.

ReplyDeletebitdefender sign-in

You’re a very skilled blogger. I have joined your feed and look forward to seeking more of your fantastic post. Also, I have shared your web site in my social networks!

ReplyDeletevisit:www.malwarebytes.com/install

very good writes. feel good after reading this. I really like this. Thank you for this blog post.

ReplyDeleteVisit: www.bitdefender.com/downloads

This blog is really very Informative and helpful. Thanks for sharing.

ReplyDeleteVisit: www.avg.com/activation

I am very thankfull to you for sharing this fantastic article , I appereciate your work .

ReplyDeletevisit: www.trendmicro.com/downloadme

Trend Micro BestBuy (trendmicro.Com/bestbuy) Antivirus is one of the most popular antiviruses that you can purchase. If you are seeking out best software application that will preserve all of your devices secure and sound, then Trend Micro Best Buy will absolutely assist you. Before you select to shop for fashion micro it is essential that you recognise approximately the sides which we have referred to in the beneath section.

ReplyDeletewww.trendmicro.com/downloadme

Spam and phishing protection –Through emails, your private and sensitive facts can additionally be hacked. Trend micro antivirus lets you find out emails which include such malicious code and protects your data and gadget from a viable malware assault or breach.

ReplyDeleteSo proper right here are some of the most important points of Trend Micro Antivirus which you can experience in your gadget. They have one-of-a-type plans and presents to pick from which allows you to pick out the splendid choice to your requirements.

www.trendmicro.com/bestbuypc

I am not very good at writing, after I saw this very good website, I became excited to write smarter.

ReplyDeleteVisit: www.trendmicro.com/downloadme

Thanks for the post and effort! Please keep sharing more such blog.

ReplyDeleteVisit: webroot.com/safe

Thanks for sharing a great post!

ReplyDeletemcafee.com/activate

The information above is very good to me, thanks for sharing!

ReplyDeleteVisit: www.bitdefender.com/downloads

Cool you write, the information is very good and interesting.

ReplyDeleteVisit: www.malwarebytes.com/install

This blog is really very Informative and helpful. Thanks for sharing.

ReplyDeleteVisit: Visit W3Schools

A big thank you for your blog article.Thanks Again. Want more.

ReplyDeleteVisit: www.kaspersky.com.au/downloads

The information above is very good to me, thanks for sharing!

ReplyDeleteVisit: www.kaspersky.com.au/downloads

This blog is really very Informative and helpful. Thanks for sharing.

ReplyDeleteVisit: My Kaspersky Login

Thanks for sharing it with us. I enjoyed the reading.

ReplyDeletewww.avg.com/retail

This blog is really very Informative and helpful. Thanks for sharing.

ReplyDeleteVisit: www.avg.com/activation

Thank you for sharing this useful information, I will regularly follow your blog.

ReplyDeleteVisit: www.webroot.com/safe

A big thank you for your blog article.Thanks Again. Want more.

ReplyDeleteVisit: www.avg.com/activation

Cool you write, the information is very good and interesting.

ReplyDeleteVisit: www.avg.com/retail

The information above is very good to me, thanks for sharing!

ReplyDeleteVisit: www.avg.com/activation

Cool you write, the information is very good and interesting.

ReplyDeleteVisit: reinstall malwarebytes paid version

A big thank you for your blog article.Thanks Again. Want more.

ReplyDeleteVisit: www.avg.com/retail

A big thank you for your blog article.Thanks Again. Want more.

ReplyDeleteVisit: reinstall malwarebytes paid version

thanks for the tips and information..i really appreciate it.

ReplyDeleteVisit: webroot.com/safe

The information above is very good to me, thanks for sharing!

ReplyDeleteVisit: webroot.com/safe

This blog is really very Informative and helpful. Thanks for sharing.

ReplyDeleteVisit: mcafee.com/activate

Hey there, I’m David. I’m a software engineer living in Sussex, NJ 07461, USA. I am a fan of web development. I’m also interested in Cyber security, cryptography, malware, social engineering, internet and new media. You can visit my company website with a click on the button above.

ReplyDeleteMcafee.com/activate| Norton.com/setup | Webroot.com/safe

Nice blog, thank you so much for sharing this informative blog. Get creative website design by ogen info system for your business. Visit: aol desktop gold download

ReplyDeleteThe decor is fantastic and looks very elegant. Thanks for sharing this post with us! Hope to read more from you! Visit: webroot.com/safe

ReplyDeleteNice post! This is a very nice blog that I will definitively come back to more times this year!

ReplyDeleteVisit: www.webroot.com/safe

Thanks for Sharing Quality information ....

ReplyDeleteVisit: www.trendmicro.com/bestbuypc

Computer security is the process of preventing and detecting unauthorized use of your computer. Prevention measures help you stop unauthorized users from accessing any part of your computer system.

ReplyDeleteVisit: www.malwarebytes.com/install

Xfinity Connect app is popular for its features and functions now available with all new users interface and advance security features.

ReplyDeleteVisit: comcast email sign in

very informative blog updates .

ReplyDeleteVisit: www.webroot.com/safe

I am very thankfull to you for sharing this fantastic article , I appereciate your work .

ReplyDeleteVisit: www.webroot.com/safe

Aol Desktop Gold Download

ReplyDeleteNice blog, thank you so much for sharing this informative blog. Get creative website design by ogen info system for your business.

WWW.WEBROOT.COM/SAFE

ReplyDeleteNice post. Thanks for sharing! I want people to know just how good this information is in your article. It’s interesting content and Great work.

www.webroot.com/safe

ReplyDeleteNice post. Thanks for sharing! I want people to know just how good this information is in your article. It’s interesting content and Great work.

I think this is one of the most significant information for me. And i’m glad reading your article. Thank for sharing!

ReplyDeletewww.webroot.com/safe

www.trendmicro.com/bestbuypc

ReplyDeleteThanks for sharing the excellent information. Keep your good work.

www.malwarebytes.com/install

ReplyDeleteNice blog, thank you so much for sharing this informative blog. Get creative website design by ogen info system for your business.

I found this is an informative and interesting blog so I think so it is very useful and knowledgeable. I would like to thank you for the efforts you have made in writing this blog.

ReplyDeleteAmazon affiliate site

ReplyDeleteaol desktop gold download – What are you waiting for in your scheme to aol gold desktop download and start the interesting voyage of exploring this software’s unique characteristics. You can always refer to AOL Desktop Gold for all kinds of assistance where your query will be answered.

aol desktop gold login

Security software is a type of software that defends and protects your computer, network, or any computing-enabled device. Once you download and install the webroot on your device via

ReplyDeletewebroot.com/safe, It takes very low space in your device and provides maximum protection.

Great post with wonderful piece of information. I'm really glad that I came across your article. Learning a lot from here. Keep us updated. www.bitdefender.com/central

ReplyDeleteI found this is an informative and interesting blog so I think so it is very useful and knowledgeable. I would like to thank you for the efforts.

ReplyDeletewww.trendmicro.com/activation

Excellent blog. Very interesting to read. I really love to read such a nice article. Thanks! keep rocking.

ReplyDeletewww.kaspersky.com/downloads

ReplyDeletewebroot is an antivirus. with the help of an anti-virus, we can remove all types of viruses in the device .webroot is a cloud base software that can help to remove viruses in the computer. it is too easy to download this software. with the help of webroot, we can scan the computer and remove all the malicious and suspicious programs. its have lots of amazing features. There’s also a set of useful system repair options such as ‘Set system policies to defaults’. This allows it to fix situations such as when a malicious process has disabled your Task Manager or Registry or forced any other policy-type restriction.

www.webroot.com/safe

ReplyDeleteFrom business to education, shopping to banking, food to a medical facility; everything is now available online in this digital age. If you are a regular internet user, then you probably desire a web browser that works faster and Secure to use. Or, in other words, you can say that you need a desktop gold download on your device. The latest version shares an incredible browsing experience with the users and lets them browse, shop, and work under a single roof. This post is providing brief information about the desktop gold download on your device. The guidelines are simple and easy to follow, so let move next and learn the simple instructions to complete the task.

aol 10.0 version free download

amazon affiliate wordpress website

ReplyDeleteHey guys, My name is Andrew Gaze. I have expertise in wordpress website development. I work on the many wordpress website like for affiliate marketing, travel affiliate, charitable trust, agency, customer service, autopilot wordpress website & other ecommerce projects. I have also command over the seo of the website. I am highly aware of working on the project in deadline and customer satisfaction is our first priority. I will create wordpress amazon autopilotṣ affiliates also. So, let's do work together.

amazon affiliate wordpress website

"Kaspersky Free is a completely free security solution that does not show any

ReplyDeletethird-party advertisements. Kaspersky Free also does not collect your personal data.

We value your privacy. Kaspersky Total Security is an overall good internet security suite. to click this link kaspersky antivirus"

This comment has been removed by the author.

ReplyDeleteDo you have an HP printer? It needs some software to improve the performance of the hp printer, like driver software, Bluetooth driver, wifi driver, smart app, scanner software, scan doctor. These all software are performing differently by respective works like scanning your hp printer performance, identifying the printer errors, checking ink cartridge level and also paper struck problems. So you need this type of software contact our website why my hp printer in error state (smart app, scan doctor, wifi driver, BlueTooth driver, driver software, scanner software)

ReplyDeleteI want a wireless HP printer for wireless printing favor. Wireless printing technology permits the users to print the files wirelessly simply. It makes users feel free and the best way to get the printout of any file easily. In the initial stage, I have opened 123.hp/setup in my special chrome browser and have typed the model number of my wireless printer in the shown box of 123.hp.com. After this process, I execute the show to finish the setup process. I am confronting issues in this process, so I need to take the unique help from an online technician. So anyone can assist me to set up an HP wireless printer via hp printer wireless setup

ReplyDeletemcafee antivirus download

ReplyDelete==========================

"mcafee is an antivirus software providers that secure your computer for virus , worms ,trojens and other mailcious program .it provides full range of

security product like antivirus , firewall etc .you have to do mcafee antivirus download

Am I a small business owner and having the essentials of a printer. So as per my needs, I suggest an HP printer. HP printer is totally an easy printing machine for users. This printing device has advanced and amazing features, so I suggest this brand most. I look further to using the HP printer via hp easy scan download , but I don’t have enough skill to complete the setup process. rapidly, I look for the technician assists to help me with the HP printer setup procedure. So please someone can refer me to the proper instructions to set up an HP printer.

ReplyDeleteAm I a small business owner and having the essentials of a printer. So as per my needs, I suggest an HP printer. HP printer is totally an easy printing machine for users. This printing device has advanced and amazing features, so I suggest this brand most. I look further to using the HP printer via Find WPS Pin For Hp Printer, but I don’t have enough skill to complete the setup process. rapidly, I look for the technician assists to help me with the HP printer setup procedure. So please someone can refer me to the proper instructions to set up an HP printer.

ReplyDeleteDo you have an HP printer? It needs some software to improve the performance of the hp printer, like driver software, Bluetooth driver, wifi driver, smart app, scanner software, scan doctor. These all software are performing differently by respective works like scanning your hp printer performance, identifying the printer errors, checking ink cartridge level and also paper struck problems. So you need this type of software contact our website hp deskjet 2541 driver download (smart app, scan doctor, wifi driver, BlueTooth driver, driver software, scanner software)

ReplyDeleteIn the event that you are a client of HP laserjet pro fax and searching for a source that can give you definitive advances and documents for the setup of HP laserjet pro fax, mind me, you should visit hp laserjet error code 0-19. This is one step goal to find all the documents and driver applications related to all the HP laserjet pro fax models. Along with this, we have indicated here a good and easy process for hp lesarjet pro fax setup. So for what reason would you say you are stopping? Hit the connection and appreciate top-tier printing results.

ReplyDeleteIf you need to use any type of model of HP Officejet pro fax for your printing needs, you can set up your suggested model number of HP Officejet pro fax using

ReplyDeletehp Officejet pro 8710 setup. This website assists you to set up the suggested model number of your HP Officejet pro fax in suitable ways. First of all, you want to open this link in your suggested browser and download the application step by step. After that, you want to perform the shown steps in indirect ways. If you get jammed in the procedure, you can take a good technician from an online technical specialist.

We can instruct you properly if you need to set up an HP Officejet Pro fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open hp officejet pro 6978 fax setup and open it in the internet browser. then, you should type the model number of your HP Officejet Pro fax in the shown box of 123.hp/setup. You can download the personal drivers of your HP Officejet Pro fax. After this process, you may get inserted into setting up the HP Officejet Pro fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP Officejet Pro printer using 123.hp/setup.

ReplyDeleteI want a wireless printer for wireless printing help. I trust in using HP Officejet pro fax products for my wireless printer function. HP Officejet pro fax is an excellent printing system, so legion users choose it for their printing needs. I want to set up an HP officejet pro fax with the assistance of hp officejet pro 6978 fax driver download. First of all, I have opened this link in my suggested browser. Then, I entered the model number of my wireless printer in the shown box. I am finishing this step to introduce a printer driver or application for the HP officejet pro fax setup procedure. After this step, I am getting stuck on finishing the HP officejet pro fax using 123.hp.com/setup. I am facing technical issues to complete the HP officejet pro fax setup procedure. So anyone can share the easy ways to set up an HP officejet pro fax with the assistance of 123.hp.com/setup.

ReplyDeleteWe can instruct you properly if you need to set up an HP Officejet Pro fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about hp officejet pro 6978 fax wireless setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type the model number of your HP Officejet Pro printer in the shown box of 123.hp/setup. You can download the personal drivers of your HP Officejet Pro printer. After this process, you may get inserted into setting up the HP Officejet Pro fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP Officejet Pro fax using 123.hp/setup.

ReplyDeleteIn the event that you are a client of HP Envy fax and searching for a source that can give you definitive advances and documents for the setup of HP printer, mind me, you should visit Hp Envy Fax. This is one step goal to find all the documents and driver applications related to all the HP Envy fax models. Along with this, we have indicated here a good and easy process for hp printer setup. So for what reason would you say you are stopping? Hit the connection and appreciate top-tier printing results.

ReplyDeleteIt would be pretty difficult to set up their HP Fax Setup in a suitable way. The unprotected printer users may vary for generative instruction for the printer tool. That’s why; our technical engineers have fixed to advance a website i.e.,hewlett packard faxes to give more information concerning HP Fax setup. So, if some users give access to this link, they will get to study how helpfully printers should be set up. Once the printer has effectively been set up also in a direct format, the users can flexibly print anything from their HP Fax system.

ReplyDeleteThe direct answer is certainly you can set up on your own. If you have just bought a new HP deskjet fax and have no idea how to set it up. then you are at the right site Hp deskjet 2622 printer fax setup. will assist you to set up your printer by providing step-by-step instruction which will make it appear as though a cake stroll to you. Just by going through the points, you will be able to set up your printer and get the printing started. further problems, feel comfortable to get in touch with us by calling on our 24x7 helpline customer support and the technician will solve your query.

ReplyDeleteI want a wireless printer for wireless printing help. I trust in using HP Officejet fax products for my wireless printer function. HP Officejet fax is an excellent printing system, so legion users choose it for their printing needs. I want to set up an HP officejet fax with the assistance of Hp officejet 3830test fax setup. First of all, I have opened this link in my suggested browser. Then, I entered the model number of my wireless printer in the shown box. I am finishing this step to introduce a printer driver or application for the HP officejet fax setup procedure. After this step, I am getting stuck on finishing the HP officejet printer using 123.hp.com/setup. I am facing technical issues to complete the HP officejet fax setup procedure. So anyone can share the easy ways to set up an HP officejet fax with the assistance of 123.hp.com/setup.

ReplyDeleteAm I a small business owner and having the essentials of a printer, So as per my needs, I suggest an HP Officejet Pro fax? HP Officejet Pro fax is totally an easy printing machine for users. This printing device has advanced and amazing features, so I suggest this brand most. I look further using the HP Officejet Pro fax via hp officejet 6830 test fax , but I don’t have enough skill to complete the setup process. rapidly, I look for the technician to help me with the HP Officejet Pro fax setup procedure. So please someone can refer me to the proper instructions to set up an HP Officejet Pro fax.

ReplyDeleteIn the event that you are a client of HP Officejet Pro Fax setup and searching for a source that can give you definitive advances and documents for the setup of HP Officejet Pro fax setup , mind me, you should visit Hp officejetpro 8710 test fax setup . This is one step goal to find all the documents and driver applications related to all the HP Officejet Pro fax setup models. Along with this, we have indicated here a good and easy process for hp printer setup. So for what reason would you say you are stopping? Hit the connection and appreciate top- tier printing results.

ReplyDeleteAm I a small business owner and having the essentials of a printer, So as per my needs, I suggest an HP envy printer? HP envy printer is totally an easy printing machine for users. This printing device has advanced and amazing features, so I suggest this brand most. I look further using the HP envy printer via hp printer support, but I don’t have enough skill to complete the setup process. rapidly, I look for the technician to help me with the HP envy printer setup procedure. So please someone can refer me to the proper instructions to set up an HP envy printer.

ReplyDeleteI want multiple printers for scanning and copying help. I have chosen to pick an HP Xerox Driver Download.I am a new user of HP products, so I don’t know anything about its features and tasks. I need to start a multiple HP Xerox Driver Download with the help of 123.hp.com/setup.I am using my knowledge to open it in the internet browser and type my model number. After this command, I am finishing the next technical procedure. At the center of the process, I am experiencing issues. So I am sharing this issue with you too, guys. Could anyone refer to the right way to set up an HP Xerox Driver Download printer using Xerox driver download

ReplyDeleteDo you have an HP printer? It needs some software to improve the performance of the hp printer, like scan doctor. These all software are performing differently by respective works like scanning your hp printer performance, identifying the printer errors, checking ink cartridge level and also paper struck problems. So you need this type of software contact our website HP Print and Scan Dactor

ReplyDeleteDo you have an HP smart app? It needs some software to improve the performance of the hp printer, like smart app. These all software are performing differently by respective works like scanning your hp printer performance, identifying the printer errors, checking ink cartridge level and also paper struck problems. So you need this type of software contact our website HP Smart app for pc

ReplyDeleteI have chosen to pick an HP smart app. I am a new user of HP products, so I don’t know anything about its features and tasks. I need to start a multiple HP smart app with the help of 123.hp.com/setup.I am using my knowledge to open it in the internet browser and type my model number. After this command, I am finishing the next technical procedure. At the center of the process, I am experiencing issues. So I am sharing this issue with you too, guys. Could anyone refer to the right way to set up an HP smart app printer using HP smart app

ReplyDeleteDo you have an HP printer? It needs some software to improve the performance of the hp printer, like driver software, smart app, scanner software, scan doctor. These all software are performing differently by respective works like scanning your hp printer performance, identifying the printer errors, checking ink cartridge level and also paper struck problems. So you need this type of software contact our website hp smart app (smart app, scan doctor, scanner software)

ReplyDeleteI want multiple printers for scanning and copying help. I have chosen to pick an HP envy printer. I am a new user of HP products, so I don’t know anything about its features and tasks. I need to start a multiple HP envy printer with the help of 123.hp.com/setup.I am using my knowledge to open it in the internet browser and type my model number. After this command, I am finishing the next technical procedure. At the center of the process, I am experiencing issues. So I am sharing this issue with you too, guys. Could anyone refer to the right way to set up an HP envy printer using 123.hp.com/envy 5055

ReplyDeleteI want multiple printers for scanning and copying help. I have chosen to pick an HP printer. I am a new user of HP products, so I don’t know anything about its features and tasks. I need to start a multiple HP printer with the help of 123.hp.com/setup.I am using my knowledge to open it in the internet browser and type my model number. After this command, I am finishing the next technical procedure. At the center of the process, I am experiencing issues. So I am sharing this issue with you too, guys. Could anyone refer to the right way to set up an HP printer using 123.hp.com/setup

ReplyDeleteI have chosen to pick an HP smart app. I am a new user of HP products, so I don’t know anything about its features and tasks. I need to start a multiple HP smart app with the help of 123.hp.com/setup.I am using my knowledge to open it in the internet browser and type my model number. After this command, I am finishing the next technical procedure. At the center of the process, I am experiencing issues. So I am sharing this issue with you too, guys. Could anyone refer to the right way to set up an HP smart app using hp smart app

ReplyDeleteWe can instruct you properly if you need to set up an HP Officejet printer using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP Officejet printer in the shown box of 123.hp/setup. You download the personal drivers of your HP Officejet printer. After this process, you may get inserted into setting up the HP Officejet printer properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP Officejet printer hp officejet 100 printer setup

ReplyDeleteDo you meet your hp printer in printer offline because of any interrupted in wireless connection, disconnection printer receiver problem, printer not connected with the devices, so it may be very difficult or easy to fix based on their type of problem so feel free, we are here for fixing your hp printer offline problem by well-experienced printer technician by through online session of our website hp printer in offline

ReplyDeleteWe can instruct you properly if you need to set up an HP Officejet printer using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP Officejet printer in the shown box of 123.hp/setup. You download the personal drivers of your HP Officejet printer. After this process, you may get inserted into setting up the HP Officejet printer properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP Officejet printer using hp officejet 100 mobile printer

ReplyDeleteWe can instruct you properly if you need to set up an HP laser Pro fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP Officejet Pro printer in the shown box of 123.hp/setup. You download the personal drivers of your HP Officejet Pro printer. After this process, you may get inserted into setting up the HP laser Pro fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP laser Pro fax using HP LaserJet Pro M479fdw fax setup

ReplyDeleteWe can instruct you properly if you need to set up an HP Officejet Pro fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP Officejet Pro fax in the shown box of 123.hp/setup. You download the personal drivers of your HP Officejet Pro printer. After this process, you may get inserted into setting up the HP Officejet Pro printer properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP Officejet Pro fax using HP OfficeJet Pro 9015 fax setup

ReplyDeleteWe can instruct you properly if you need to set up an HP officejet fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP deskjet fax in the shown box of 123.hp/setup. You download the personal drivers of your HP officejet fax. After this process, you may get inserted into setting up the HP officejet fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP deskjet fax using We can instruct you properly if you need to set up an HP officejet fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP officejet fax in the shown box of 123.hp/setup. You download the personal drivers of your HP deskjet fax. After this process, you may get inserted into setting up the HP officejet fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP officejet fax using HP OfficeJet Pro 8025 fax wireless setup

ReplyDeleteWe can instruct you properly if you need to set up an HP laserjet fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP laserjet fax in the shown box of 123.hp/setup. You download the personal drivers of your HP laserjet fax. After this process, you may get inserted into setting up the HP laserjet fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP laserjet fax using HP LaserJet Pro M479fdw fax setup

ReplyDeleteWe can instruct you properly if you need to set up an HP OfficeJet fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP OfficeJet fax in the shown box of 123.hp/setup. You download the personal drivers of your HP OfficeJet fax. After this process, you may get inserted into setting up the HP deskjet fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP OfficeJet fax using HP OfficeJet Pro 9015 fax setup

ReplyDeleteWe can instruct you properly if you need to set up an HP officejet fax using 123.hp/setup. You can do the setup process easier if you have the correct technical knowledge about 123.hp/setup. First of all, you must go to open 123.hp/setup and open it in the internet browser. then, you should type t can model the number of your HP officejet fax in the shown box of 123.hp/setup. You download the personal drivers of your HP officejet fax. After this process, you may get inserted into setting up the HP officejet fax properly. If you don’t have any manual or choice, you can take the specialized expert instruction or assistance for completing the setup process of the HP officejet fax using HP OfficeJet Pro 7740 Fax

ReplyDeleteDo you have an HP printer? It needs some software to improve the performance of the hp printer, like Gmail. These all software are performing differently by respective works like scanning your hp printer performance, identifying the printer errors, checking ink cartridge level and also paper struck problems. So you need this type of software contact our website :can i send a fax from my gmail(Gmail).

ReplyDeleteDo you have an HP printer? It needs some software to improve the performance of the hp printer, like HP Fax. These all software are performing differently by respective works like scanning your hp printer performance, identifying the printer errors, checking ink cartridge level and also paper struck problems. So you need this type of software contact our website :can i send a fax from my gmail (HP Fax).

ReplyDeleteGiving the care that your child needs

ReplyDeleteAre you constantly worried about your kid during your office hours because they are alone? Are you hunting for in home nursing services for the same?

We understand it's not easy to hire a nanny and expect them to adjust with your family. But with professionals and experienced ones at Desi Domestic Service LLC, we make it possible.

Desi Domestice Service can help you with the same. We have helped many families with our in home nursing services. We can help in taking care of your naughty little one as well as your parents and grandparents. Our team of trained and experienced nannies and nurses will ensure that your family can feel the same warmth of love like they used to do in your presence.

ReplyDeleteHP Deskjet 2130 setup serves all your wants ranging from easy needs to even wireless function:HP Deskjet 2130 Printer. The printer gives high-quality printing of images and reports, and the properties of your printer are very low.

ReplyDeleteIf you're new to HP printers, follow the setup instructions to get started with printing

ReplyDelete123.hp.com

123.hp.com